Email Us

zhan@tjlulu.com/zhanlulu6@gmail.comEnglish

×

Email Us

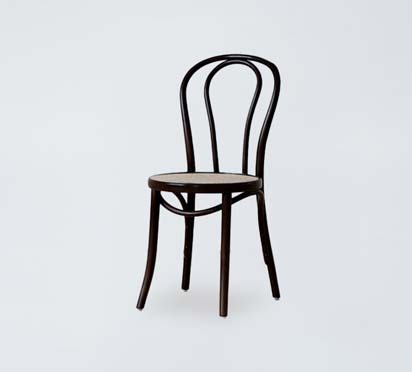

zhan@tjlulu.com/zhanlulu6@gmail.comHave you ever noticed the narrow gap on the side edge of high-end solid wood furniture, especially redwood furniture? Next, let's take a look at why real wood tables and chairs need to leave an expansion joint.

Wood has a small longitudinal shrinkage and usually, no expansion joint is needed at both ends. Some manufacturers leave expansion joints on all four sides, which looks relatively good. A solid wooden dining table manufacturer does not leave expansion joints when making furniture, but not leaving does not necessarily mean that there is none. Because the manufacturer does not have absolute control over the drying of the wood, the moisture content of the wood is generally higher than that of the air, so even if the expansion joint is not left during production, there will be seams after the furniture is made. And a considerable number of furniture have seams regardless of the wet and dry seasons, but the size is different.

In areas with large differences in environmental humidity throughout the year, expansion joints are a must. When the air humidity is high in the rainy season, although the wood has been artificially dried, the wood will still absorb moisture during the furniture-making process, resulting in an increase in volume. Generally, no expansion joint is needed. In the dry winter climate, expansion joints may also appear; when furniture is made from artificially dried wood in spring and winter, an expansion joint is usually left, otherwise, when the humid summer comes, the large edge will swell and be damaged.

Expansion joints are designed to prevent furniture edges or corner tenons from cracking when the wood is shrunk or swollen due to external environmental influences, causing the furniture components to become loose and unable to be used normally. In order to reduce the deformation of wood, a strict drying process is required before the wood is made into furniture, which may take more than a month. In order to control the quality, the moisture content of the products sold to different regions is also different for standard solid wooden dining chair manufacturers.

Above is the reason why the solid wood dining table and chair need to leave the expansion seam, hoping to help everyone. If it is solid wood furniture, then the desktop, panel part, and surface will not generally have an expansion seam. If there is, it may be due to two reasons: one is that the desktop board is a frame structure, and the other is that there are other special processes or materials on the desktop. Among them, the frame structure is the most commonly used in plate wood furniture, pay attention to distinguish. Finally, remind you that the expansion seam is the "self-protection system" of solid wood dining tables and chairs. Don't worry if the size is uneven, and most of them will return to their original state after the seasonal changes.

Our sales will contact you in 24 hours.

Quick Links

Call

+86 22 25791779Address

Rm601, Suite B, Haowei Building, Third Avenue, Teda, Tianjin, ChinaCopyright ©Tianjin Lulu International Trade Co., LtdAll Rights Reserved.